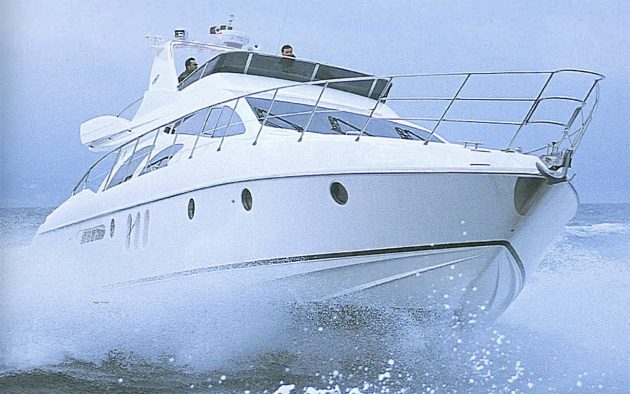

As boat stylists become more adventurous, an Azimut still stands out. But is there more to the Azimut 62 than pointy shark-fin windows, asks Tony Jones

Azimut have a solid reputation for innovating wisely, particularly in squeezing custom-yacht features into their production range.

Ever since their impressive AZ54 (MBY October 1995) redefined what we could expect from a mid-50ft (15m) flybridge cruiser, Azimut have been introducing ‘big boat’ features, such as the central positioning of the lower helm station on what is effectively a mini bridge deck, and an electrically adjustable captain’s chair.

But a 62-footer is another rung further up the ladder from the mid-fifties. The Azimut 62 shares some styling with the Azimut 55 (MBY March 2002): the shark’s fin, ellipse and oval Bannenberg-style windows; and the gratifyingly practical upright radar arch with vestigial winglets.

There seems to have been a competition between many boatbuilders (Azimut included) over the past few years to see who can produce the lowest, most rearward mounted – and therefore useless – radar arch. Not now.

The positioning also makes it easier to crane the tender over the side from its chocks at the aft end or the flybridge. The Azimut 62, indeed, is a very practical boat throughout.

For instance, the hinged centreline passerelle, the teak step in the coaming and the removable cushion on the aft bench seat eliminate any need for acrobatics when boarding, and the passerelle doubles up nicely as a PWC crane.

The cockpit is simply but logically laid out. Large aft cleats are mounted in full view, at the right height, on substantial plinths in each aft corner, with useful oddments lockers beneath.

The freestanding cockpit table and chairs live in a cupboard below the flybridge steps. A single transom gate to starboard gives access to the bathing platform.

Behind a smoked acrylic door in the cockpit side buttress just above the shore-power locker we find Azimut’s typically comprehensive safety panel, with instantly accessible electrical master switches, an emergency stop button, and beefy manual pull handles for the engineroom fire-extinguishers and intake shut-off flaps.

Azimut have been doing this for some years now. It beats me why other builders are so reluctant to follow suit.

Elsewhere on deck everything is as it should be, with decent side decks, good guardrails and a step-through pulpit. As with the 55, there are no low-level spring cleats aft – a surprising omission.

The well-arranged bow locker has plenty of room for fenders and the chain itself is held in a bucket mounted just under the deck.

On other boats, it’s often very difficult to sort out tangles when the chain is out of reach down in the bottom of the vee.

There are a few minor criticisms of the deck arrangements. The cockpit furniture locker needs an overboard drain; the position of the manual bilge pump, buried at the back of a starboard cockpit locker, makes it hard to use; and corrosion was already evident on the chain locker’s uncharacteristically cheap latches.

Also, the transom gate is one of those trendy jobs relying on a ‘drop and lock’ hinge to keep it shut.

Although the Azimut 62’s seemed fairly solid, it is fundamentally bad engineering not to spread the load between both ‘gate posts’: think of the bending stresses on the GRP if anyone fell heavily against the gate.

But on the bathing platform it was refreshing to find an RCD compliant pull-out swim ladder, one that could be deployed without help by someone already in the water.

Up on the flybridge, Azimut have decided that, as on the 55, having the passengers lolling around where the helmsman can see them is the main priority.

So the helm station is over to port with an aft-facing, curved sunbed-cum-lounger opposite.

The downside is that passengers can’t easily sit up and look forward when under way. Good wind protection is provided by the taller than average tinted destroyer screen.

The non-adjustable helm seat (presumably all Azimut helmsmen are the same size) is backed by a quadrant shaped wet-bar, and the remainder of the starboard side is taken up with an L-shaped settee and plinth-mounted diniing table.

Driving the Azimut 62

Apart from the flybridge seat, there are some other small criticisms that can be made of the helm positions.

The neat chart area to starboard of the lower helm, where the navigator can perch comfortably on the end of the dinette sealing, could do with an instrument drawer or tray, and it would make sense to swap the positions of the VHF and the radar to bring the latter more directly into the helmsman’s eyeline.

The Azimut 62’s lower helm

Paired-up minor engine instruments would be preferable to the current mirror-image layout and the switches could do with being split up into functional blocks.

Upstairs, the rear, lower face of the instrument console should be cut away to provide more foot room, and cup holders are in short supply.

But the provision of a handheld searchlight as well as the remote controlled unit on top of the radar arch is to be applauded.

A top speed of 31 knots and cruising in the mid-to-upper twenties is about par for the course.

Acceleration is poor: 1,000rpm to a top rating of 2,300rpm takes 23.5 seconds, with full speed coming up about five seconds after that.

There’s a barely perceptible hiccup at 1,750rpm caused by the sequential turbocharging of the MTU 2000 series V8s.

Up to this point, only the turbocharger on the right-hand bank of cylinders is working, then the second turbocharger cuts in as airflow requirements increase.

But the situation is further complicated by the engine mapping that limits the rate at which the revs are allowed to rise beyond 1,400rpm.

It’s all to do with emissions, of course, and very effective it is – at the cost of performance.

But then a 62ft (19m) flybridge cruiser is not designed for drag racing.

The Azimut 62 in full flight

The Fadec (full-authority digital engine control) makes it impossible to mishandle the throttles: there’s a very strict computer sitting between your right hand and tl1e injection pump.

There is even a ‘down ramp’ that controls the rate of rpm decrease if you slam the throttles.

Despite their power, the engines sound subdued and unstressed at cruising speed, and Azimut have done a good job to keep saloon noise levels to the mid-70s.

ln a Force 5 with lumpy and confused seas the Azimut 62 rode well, if not quite as well as the latest Olesinski-designed Fairline and Princess hulls with their exceptionally fine forefoots.

This was particularly noticeable if the boat wasn’t dead upright or the seas were coming from broad on the bow, but Med designers have always tended to concentrate on planning efficiency in fairly calm conditions, rather than the ability to battle upwind in a blow.

Trimming the bow down didn’t help much, relegating the trim tabs to the job of keeping the boat upright in a beam wind.

When it comes to manoeuvring at speed, the Azimut 62 is surprisingly hard work, very much like the 55, which had a large turning circle and where agility was conspicuous by its absence.

In our test of the 55, we speculated that the reluctance to change direction might have been due to having two-thirds of a ton of water under the forward berth.

But having now seen both boats out of the water, I think it is more likely to be a function of rudder size and shape.

Prior to the 55 and 62, Azirmut followed Olesinski practice with a rudder form (developed with a certain amount of trial and error over an extensive period) that was long and narrow – but modified with squared-off tips.

The Azimut 62’s radar arch gets the scanner where you want it: up high with an all-round view.

Long means they extend into the free water flow beneath the hull; narrow means a high aspect ratio for maximum lift and minimal tunnel blocking on full lock; while squared off gives them the greatest possible surface area.

For some reason, Azimut have decided to make the rudders on the 55 and 62 shorter and broader, and have further reduced the area by rounding off the forward bottom corner.

This seems to be a case of Azimut innovating unnecessarily, of someone trying to fix something that ain’t broke.

Accommodation aboard the Azimut 62

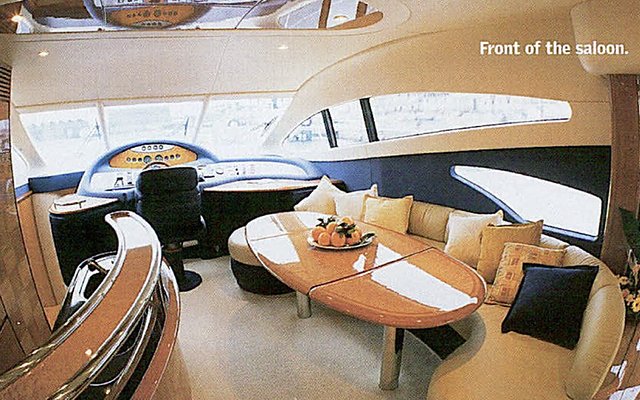

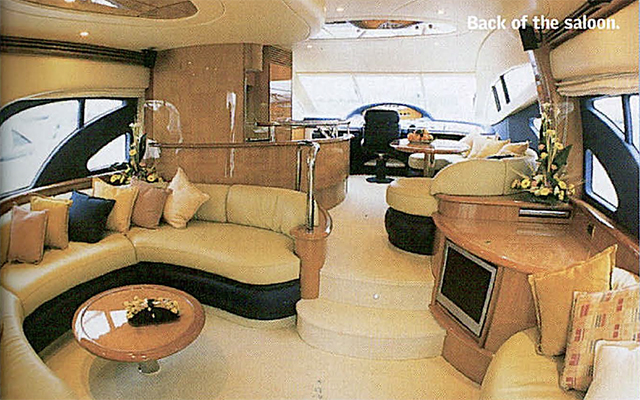

Inside, on the main deck, Azimut have once again provided a dramatically sculpted and superbly equipped central helm station.

The saloon itself is split, with the galley forward on the port side but at a slightly lower level than the main floor area.

As on the 55, the inboard ‘wall’ of the galley is formed by an elliptical bar unit with stowage on both sides – superbly convenient for the dinette opposite.

But the Azimut 62’s extra beam allows the sink countertops to be incorporated into the bar unit, leaving the outboard side free for more work surface, masses of stowage, and a magnificent full-height, stainless-lined fridge/freezer.

More length has also allowed the cocktail table to move from its rather quirky position on the 55 (level with the steps and abutting the forward end of the settee) to a more conventional position further aft.

Opposite, the sideboard unit contains a retracting hi-fi unit.

Overall, the Carlo Galeazzi layout is attractive and practical, and the raised forward section provides improved headroom down below, although part of me was missing the single-level saloon and raised bridge deck of the 1995 AZ54.

That was immediately forgotten, however, on going further below.

The open-topped, curved companionway to port of tl1e helm station deposits you on a ‘landing’ from where you can see forward into the bow cabin, across to the third cabin, and down and aft to the owner’s suite (which is reached by a further three steps).

This visually ties the entire sleeping accommodation space together, making it more of an integrated whole and less a collection of compartments.

The owner’s suite is laid out in similar fashion to the 55’s.

The bed is placed diagonally, freeing up the aft bulkhead for access to a spacious bathroom and walk-in wardrobe.

These provide an acoustic buffer to the engineroom, which, although you may never want to go to bed while under way, has the practical advantage of making the generator set almost inaudible at night.

Again, the 62’s greater volume provides a more generous floor area than on the 55, where the sole had to be dropped to just a few inches above the keel to give sufficient headroom. It also allows the luxury of a third bathroom ensuite to the twin-bedded side cabin.

This and the bow cabin are quite conventional, with every attempt being made to maximise stowage volume, which includes a row of good-sized, high-level lockers over the outboard berth in the third cabin.

The Azimut 62’s owner’s cabin

Other notable features of the interior are strategically placed handrails, the bevelled-edge mirrors that entirely face some doors, lockers and cupboards everywhere you look, space for a washing machine, unusual but very attractive and practical glass fronts to the cabin drawers, and the translucent acrylic basin tops -a change from Corian or marble, and much lighter physically and visually.

The joinery is exceptionally precise throughout, thanks to Azimut’s enthusiastic and intelligent adoption of Cadcam (computer-assisted design and manufacture).

In their new Avigliana factory, arrayed neatly on shelves along the walls of the fit-out shop, you can see stacks of perfectly identical wooden components, ranging from major bulkheads with the door apertures already machined out, to the tiny parts that make up the galley drawers.

Straight edges are dead straight, corners are dead square and curves are totally smooth.

The forward cabin on the Azimut 62

Azimut are also more inventive than most builders when it comes to finishing all this woodwork.

Yes, there’s plenty of high-gloss lacquer, but the tone is light and careful, and deliberate variations in the grain are used to break up the larger expanses.

This has long been a feature of the main internal doors, and is now extended to the items like the bar front.

In some ways this technique must help production, as matching large areas or veneer is expensive, but on the other hand it requires the know-how to get those panels fitting to marquetry standards.

Owner’s cabin heads

Perfection was marred on our prototype test boat by a few things like the inadequate height of the dinette back-rest, a wobbly handrail next to the settee, and shallow finger holds on some of the locker doors that would imperil many ladies’ fingernails.

And the air-conditioning controls in the third cabin would be much better up by the bedhead than just inside the door.

But these are minor details and it was gratifying to find that Azimut already bad most of them on a to-do list.

Engineering and construction of the Azimut 62

The Azimut 62’s engineroom is clean, neat and well designed, with the daily servicing items placed within easy reach.

Azimut were one of the first production builders to adopt silencer-free underwater

exhausts and now have the system off pat. Some good details are in evidence, like the rubber anti-vibration mounts to support the metal. exhaust trunking.

The engineroom is open to the lazarette at its aft end, which makes access from the cockpit easy.

There’s space to work in the engineroom.

But some form of net or divider should be provided to prevent the possibility of small items being bounced forward in rough weather and getting tangled up in the machinery.

Azimut have become cagey about releasing construction specifications and lines plans of late, but I’m confident this has more to do with an over-developed sense of commercial

secrecy than a desire to conceal any substandard details.

Their Avigliana factory is a smack-up-to-date and spotlessly clean facility that puts the moulding shops of most UK builders to shame.

Heating and air-conditioning systems come close to providing true climate control, even during the Italian summer.

The proportions of vinylester or polyester resin and hardener are computer controlled -the hardener is added immediately before the final mix is dispensed to the long-handled rollers used to wet out and compact pre-cut sections of cloth and woven rovings.

Work is carried out with an air of quiet concentration by a staff decked out in disposable white paper boilersuits. Half are them are women.

There are clean floors, permanent walkways around the moulds, no old buckets half full of solidified resin, and no radios blaring out pop music at full volume. It has a very professional air.

Azimut 62 verdict

With its undoubted stylishness, its practical points, and its reasonable price, the Azimut 62 can face squarely up to most of the competition.

And the exceptionally spacious owner’s cabin with its distinctive windows and the clever bar unit in the saloon mean that the boat has an edge over many of them.

The relative lack of high-speed agility won’t matter to most potential owners, and Azimut could almost certainly sort that out simply by going back to the old rudder design.

With just the one engine option providing such poor acceleration, a few sales may be lost to boats with Caterpillars or MANs, even though MTU have a very sound reputation and a comprehensive global dealer network.

Azimut have sufficient confidence in the 62’s future to have invested in two hull moulds from the word go: however desirable your product, an over-long waiting list means lost sales.

With such high standards of production boatbuilding these days, many buyers would rather settle for their second preference boat now if it means waiting until next season for their first choice.

Azimut don’t want their customers to have to make that decision.

I think those white-suited moulders at Avigliana are going to be pretty busy for some months to come.

First published in the July 2002 issue of MBY.

Pros

- Spacious master cabin

- Distinctive styling

- Galley/bar

- Joinery quality

- Overall build quality

Cons

- Poor acceleration

- Lack of engine choice

- High-speed handling and large turning circle

Details

Price from: £780,000 inc VAT

Price as tested: £780,000 inc VAT

Overall length: Overall length 64ft 7in (19.70m)

Hull length: 63ft Qin (19.22m)

Beam: 16ft 7in (5.05m)

Displacement: 28 tonnes light, 32 tonnes loaded (loaded = light + 100% fuel & water)

Draught: 4ft 6in (1.38m)

Air draught: 17ft 1 lin (5.47m)

Fuel capacity: 748 imp gal (3,400 litres)

Water capacity: 220 imp gal (1,000 litres)

RCD category: B (for 16 people)

Slow cruising: 23.5 knots, 394 miles@ 1,800rpm

Fast cruising: 30.2 knots, 266 miles@ 2,200rpm

Flat out: 31 knots, 233 miles@ 2,300rpm

Designer: Azimut (hull and engineering); Stefano Righini (styling and concept); Carlo Galeazzi (interior)

Contact: Med-Sale (UK)

Tel: +44 (0)1489 565555

Email: sales@medsale.net

Website: http://www.azimutyachts.net