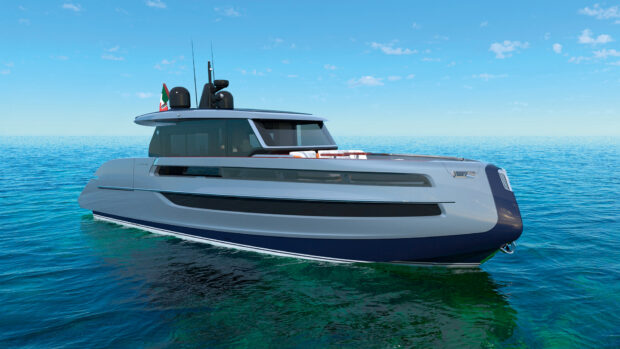

Researchers at the University of Rochester have pioneered a new hydrophobic metal that could be used to create a water-repellent superyacht

A water-repellent superyacht that is impervious to rust and corrosion could become a reality after a team of researchers from the University of Rochester pioneered a new hydrophobic metal.

By blasting a metal surface with lasers for a quadrillionth of a second, the team claim they can create micro- and nano-scale structures that effectively repel water.

As the video below shows, water slides off the surface of this hydrophobic metal at an angle of 5 degrees, as opposed to 70 degrees on a non-stick frying pan.

And although this technology could be used to create a water-repellent superyacht, it is still a long way off, says Michael Henson from Yachting Pages.

“After contacting several leading superyacht shipyards throughout Europe, it was apparent that the technology is too advanced for their R&D teams at present,” he admitted.

“Nevertheless the shipyards agreed that this technology could have a major impact on the way superyachts are built, it could be a realistic option in the future and is something they will begin monitoring.”

Potential benefits of a hydrophobic superyacht would include greater full efficiency and a much lower risk of rust or corrosion on the hull.

For many superyacht buyers money is no object, but the largest hurdle to building such a vessel is likely to be the sheer amount of time involved.

The square inch of hydrophobic metal used in the University of Rochester demonstration took an hour of laser blasting to prepare, so scaling up this operation to build a superyacht hull is likely to be a very lengthy process indeed.