After 18 months of testing eight different antifouling coatings on a Hardy 42 and a static panel, the results are finally in…

Additional reporting by Adam Fiander

Back in June 2021 we applied eight different types of antifouling onto the hull of a Hardy 42 called Raymariner. Since then it has been used around the Solent on a weekly basis until it was lifted in January this year.

The aim of the test was to compare the performance of traditional copper-based antifouls with longer-lasting, more eco-friendly alternatives, including Coppercoat and three biocide-free foul-release coatings.

The combination of ever tighter regulations controlling the type and quantity of biocides which antifouling manufacturers are allowed to use and boat owners’ own desire to do their bit for the environment means the search for new ways of keeping fouling at bay is gathering pace.

Article continues below…

Ceramic Pro review: Can this ultra-tough coating seal a boat for life?

Hempel Silic One: Is this the future of antifouling?

Most conventional antifouling paints use copper compounds suspended in a paint matrix that gradually erodes as water passes the hull, releasing the biocide at controlled rates, depending upon whether it’s a hard or soft-eroding type.

Coppercoat is an exception to the rule, because although it counts as a biocide, it uses pure copper particles set in a much harder epoxy resin that gives it a lifespan of ten years and greatly reduces the amount of copper released into the water.

Silicone-based foul-release coatings are another promising alternative, preventing fouling growth through the physical properties of its super-smooth hydrophilic surface.

BEFORE: As Raymariner looked when she was launched in June 2021

We wanted to find out if these alternative coatings perform as well as their traditional counterparts and whether their higher initial cost and fiddly multi-coat application regimes balance out with easier, more affordable annual treatments over time due to their longer lifespans.

Since silicone-based coatings work better on regularly used boats, Raymarine kindly allowed us to use their Hardy 42, Raymariner, as our test boat – although we did paint a static panel too to see how that fared.

Last year’s hot and wet weather may well have contributed to the excessive build-up of slime that greeted us when the boat was lifted in January. As you can see from the pictures, slime coated nearly all of our eight test strips, especially near the waterline.

AFTER – As she looked when she was lifted towards the end of January 2022

However, almost none of them showed any weed or barnacle growth, whereas the uncoated strips we left between some of the products were heavily fouled.

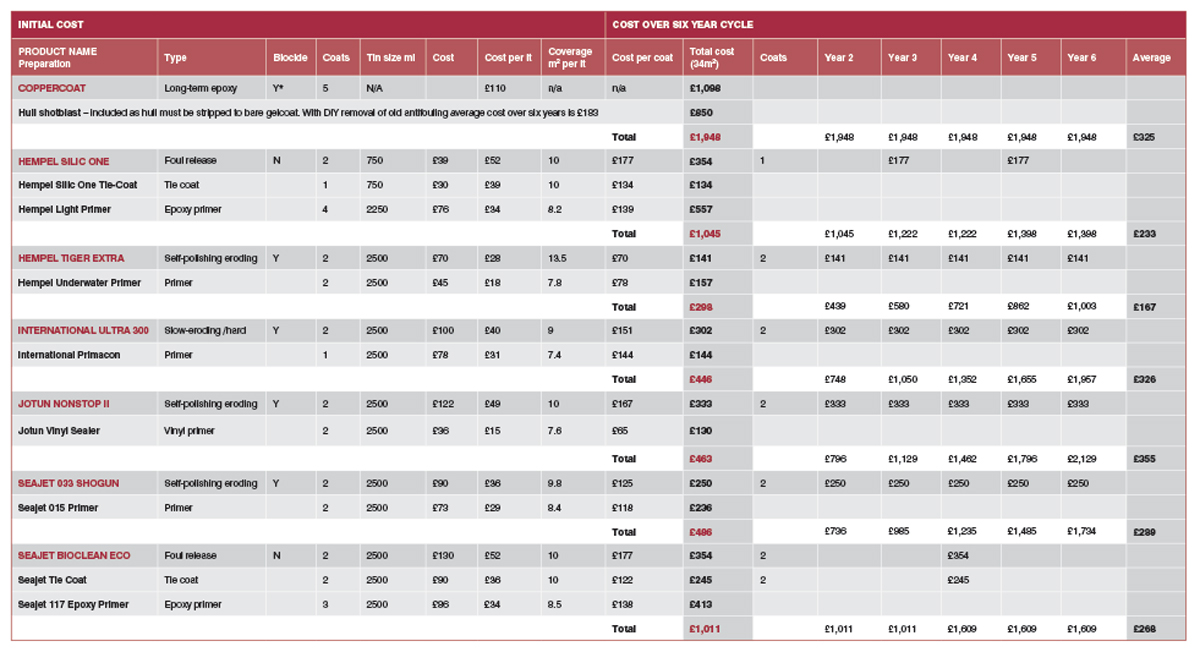

You can see a full table of costs at the foot of the page, but for the individual reviews we have quoted two prices. The first is our estimated price of the initial application to a typical 36ft boat, including any essential preparation costs such as stripping and priming (but not labour or lifting).

The second is an estimated annualised cost calculated over a six-year period. This doesn’t include labour and some coatings may last longer than their specified times, including the traditional ‘annual’ antifoulings, but we believe it gives a fairer reflection of the true cost over the long term.

18-month update

Raymariner was repainted with fresh antifoul after our test ended in January 2022, but the static panel allowed us to see how the coatings fared 18 months since the test began.

It’s important to remember that a boat would not normally sit idle and uncleaned for that length of time, making the test more challenging for all our products but especially the ‘foul-release’ coatings which rely on water movement to help shift any fouling.

Now that the boat-based test has reached its conclusion, the static panel provided a valuable cross-check for the longer term performance of the products based on a visual assessment of the stripes, a finger swipe to see how easily any fouling came away, and a sponge wipe to check if the coating itself came away too.

Like the boat, our static test panel was immersed in a Portsmouth marina location in June 2021. Apart from the effect of the tide sweeping across it, the panel has remained in situ there, fully immersed at all times for the last 18 months.

As you can see from the pictures, the coatings have, by and large, performed extremely well. Apart from silty mud covering the test stripes, there are very few signs of serious fouling having taken hold on any of the coated sections.

Even green slime – highly prevalent when Raymariner was lifted a year ago – appears to have taken a back seat in this case, perhaps because the panel has been lying in a shaded area for most of the time. Proof of how well the coatings have performed can be seen by the growth of weed and up to 10cm long sea-squirts on untreated sections.

BEFORE (left): Copper colour turns a greeny blue once immersed. AFTER (right): Some slime evident but no weed or barnacles

Coppercoat

Type: Epoxy-based non-eroding long-term biocide

Preparation: Hull-blasted back to bare GRP

Initial cost: £1,948 inc blasting & primer

Lifespan: 10 years+

Annualised cost over six years: £324

MBY rating: 4/5

Unlike the annual antifoul paints, which use a compound of copper suspended in eroding paint that gradually leaches out, Coppercoat uses pure copper powder set in a harder epoxy coating that should last for at least ten years.

It also vastly reduces the amount of copper released into the water, helping to prevent the build-up of copper in waterways, harbours and marinas.

Coppercoat can only be applied to hulls that have been stripped back to bare gelcoat and each of the five coats has to be applied wet-on-tacky. This effectively means it all has to be done during the course of a single day.

Lasts for 10 years, but has a high initial cost

Once dry, the surface needs to be burnished with 400-grit paper to expose and activate the copper. In future years, a pressure wash or scrub is all that’s required.

The results show a similar level of protection to the annual copper-based antifouls. There may be a little more slime than others but Coppercoat is a long-term solution and seven months is barely one season’s worth of use.

The initial cost is higher than most, partly because we have included the cost of blasting off the old antifoul (new boats just need sanding) but after six years the annual cost is much the same and it would continue getting cheaper after that. Nor does this take into account the substantial saving on labour time.

Before a thorough wipe-down (left) and after (right)

18-month update

Even though Coppercoat recommends an annual scrub or pressure wash to remove any surface growth, it still seems to be performing well after 18 months untouched. There was no significant fouling on the exposed copper surface, which has now adopted its characteristic blue/green colour, and minimal resistance from the swipe tests, suggesting any surface growth would fall away on a regularly used hull.

As expected of a tough epoxy based product there was no sign of the coating coming away on the sponge. Coppercoat’s claims of it being more environmentally friendly than erodible coatings.

Buy it now from coppercoat.com

BEFORE (left): Smooth rubbery surface makes it hard for fouling to grip. AFTER (right): Impressive result – no weed, barnacles or even slime

Hempel Silic-One

Type: Non-biocide, silicone based foul-release coating

Preparation: Four coats Hempel Light Primer; one coat Silic One Tie-Coat

Initial cost: £1,045 inc primer and tie coat

Lifespan: 2 years+

Annualised cost over six years: £337

MBY rating: 5/5

Silic One has the most stringent application process of our group and is best applied to a stripped hull, unless the old antifouling is in very good order, when a barrier coat of Silic Seal will enable the switch.

The process starts with four thin layers of Light Primer, a tie-coat (applied while the primer is still tacky) and two coats of Silic One with a minimum of 8hrs in between, the last of which has a 16hr minimum drying time before re-immersion.

If it sounds like an involved process that’s because it is, taking nearly three days from start to finish once drying intervals have been factored in. However, the results speak for themselves.

Best performer, but fiddly to apply

After seven months, Silic One has performed the best of our group, with no signs of weed or shell growth and the least amount of surface slime. It also wiped off exceptionally easily.

Because it has a recommended lifespan of two years (but can last for up to five years) before it needs topping up with two fresh coats, the high initial application cost is offset over time. After six years its annualised cost is similar to many of the biocide products but could prove cheaper if it lasts longer than two years.

Before a thorough wipe-down (left) and after (right)

18-month update

We had expected foul-release coatings to struggle on a static panel without any movement through the water to shift surface fouling. However, the majority of the stripe stayed remarkably clean and any slime was easily swept aside with the swipe test.

Some isolated growth can be seen at the top of the strip but this could have been caused by migration of fouling from the untreated section in-between this and the Seajet Bioclean-Eko (the other products were separated by a strip of white Trilux antifouling). So far there are no signs of any surface deterioration.

BEFORE (left): Easy to apply and leaves a smooth finish. AFTER (right): Only a thin layer of slime that wipes off easily

Hempel Tiger Xtra 7100

Type: Soft eroding biocide antifouling

Preparation: Two coats Hempel Underwater Primer

Initial cost: £297 inc primer

Lifespan: 1-2 years

Annualised cost over six years: £166

MBY rating: 4/5

While it might not be the most technically sophisticated formulation out there, for many boat owners Tiger Xtra has become a go-to product – a reliable staple and a firm favourite on the winter maintenance list.

With one of the highest per sqm coverage rates of anything tested here, applying Tiger Xtra will soon have you making decent progress across the hull in a relatively short space of time. The prospect of coating even larger than average hulls needn’t be as daunting or as expensive as you might have first imagined.

But does it work? The answer is yes. Doubtless, the regular, weekly use that Raymariner has been subject to these past seven months has helped get the best from all of our contenders (self-polishing mechanisms need movement of water across the hull) but on this evidence Tiger Xtra has performed as well as many of its more expensive rivals.

Impressive value, but needs applying every year

There was no weed or barnacle growth and the slime was a little easier to release than on some of the others. The only unknown quantity is whether this performance will continue over a longer length of time, especially if you’re cruising in warmer waters with higher fouling.

It represents such good value for money we have given it an extra star over its annual rivals.

Before a thorough wipe-down (left) and after (right)

18-month update

We were pleased to see how well the cheapest of our traditional antifouling coatings coped on the boat and the results from the panel did nothing to change this view. Our initial inspection showed no more fouling growth on this than any of the more expensive products and the finger swipe test easily shifted anything that was there.

Some of the coating surface colour did transfer onto the sponge, which is normal for a soft eroding coating, but over time it might start to wear through on a fast, regularly used boat.

BEFORE (left): Another easy to apply coating that leaves a smooth finish. AFTER (right): The usual layer of slime but a bit harder to shift than some

International Ultra 300

Type: Hard eroding biocide antifouling

Preparation: One coat Primacon

Initial cost: £444 inc primer

Lifespan: 1-2 years

Annualised cost over six years: £324

MBY rating: 3/5

Ultra 300 is a hard and relatively slow-eroding formulation that lends itself well to fast or regularly used motor boats that might wear through softer coatings too quickly.

After applying just one recommended coat of primer, we applied two good coats of Ultra 300, (total 120 microns dry), in a straightforward and fuss-free way, making life easy for the DIY applicator. Job done.

The results have been pretty good but marginally less impressive than the Micron 350, which Raymariner was coated with prior to this test, although that could be down to seasonal differences in water temperature and fouling growth rates.

Easy to apply, average performance

As expected, the Ultra was sheathed in a film of slime, thicker near the waterline, and when we tried to wipe the slime away with a damp microfibre towel, it showed quite a lot of resistance, suggesting it had taken hold quite firmly.

However, it was nothing that a jet-wash wouldn’t shift of course, and with no long beards of weed or shell growth to worry about. At an annual cost of around £324 for a typical 36ft boat it’s a solid, easy to apply performer that may last two seasons on lightly used boats.

Before a thorough wipe-down (left) and after (right)

18-month update

Although this is a traditional copper-based antifouling, it is a slow eroding hard coating designed for faster planing craft with increased water friction that might wear through softer products.

This didn’t affect its performance on our static test panel with little fouling growth over the 18 months and no sign of it starting to lose its antifouling properties. The swipe test suggests any fouling would fall away on a moving hull used regularly, while the sponge test showed only slight signs of the coating releasing itself.

BEFORE (left): Blue is one of several colours available in this range. AFTER (right): A decent result but not noticeably better than cheaper options

Jotun Non-Stop 2

Type: Soft eroding biocide antifouling

Preparation: Four coats Jotun Megacote Epoxy; one coat Megasealer Epoxy Tie-Coat

Initial cost: £464 inc primer

Lifespan: 1-2 years

Annualised cost over six years: £355

MBY rating: 3/5

As we had stripped Raymariner’s hull back to bare gelcoat to ensure a level playing field for all of our products, Jotun decided to send us their full epoxy-primer, epoxy tie-coat and combined anti-osmosis system, prior to applying the two final coats of Jotun Non-Stop 2.

While this belt-and-braces approach would make sense on a brand new hull, we felt that for the purposes of price-comparison, it would be fairer to use the cost of two coats of Jotun Vinyl Sealer – a straightforward, one-component product that we have been assured can also be applied on to bare gelcoat hulls.

As the name suggests, Jotun Vinyl Sealer is ideal for those looking to antifoul an already treated hull in good condition and is a readily available product the DIY user would be more inclined to buy.

Slime is easy to shift, but this antifoul is pricier than most

The results in January 2022 showed a good overall performance, broadly similar to the other copper-biocide products, with no significant weed or shell growth to talk about but a thickish layer of slime that shifted quite easily with the towel test.

Even if you opt to use only the basic vinyl primer for the initial application, the annualised cost still makes this one of the pricier options in our test so it will be interesting to see if it lasts longer than the cheaper options over a longer period of time.

Before a thorough wipe-down (left) and after (right)

18-month update

This premium priced self-polishing coating uses ion exchange technology to ensure a steady release of biocides throughout the year, even when the boat is not being regularly used. While it performed well it wasn’t noticeably better than some of its cheaper competitors.

However, it did have the highest degree of coating surface being released onto the sponge suggesting it was eroding consistently even without regular boat movement – a good thing as long as it has been applied in sufficient quantity.

BEFORE (left): Needs a good stir but paint goes on evenly. AFTER (right): Another solid performer with no shell or weed growth

Seajet 033 Shogun

Type: Soft eroding biocide antifouling

Preparation: Two coats Seajet 015 Primer

Initial cost: £489 inc primer

Lifespan: 1-2 years

Annualised cost over six years: £292

MBY rating: 3/5

When we heard about a new non-biocide antifoul release coating from Seajet, it made sense to compare it alongside Seajet Shogun, its best-selling, copper-based formulation.

Backed by the commercial resource of Chugoku Marine Paint, Seajet first appeared in the UK about 20 years ago and carved a niche for technical-quality antifouls.

One thing we found when applying Shogun is that the copper and zinc solids sink to the bottom of the tin so it’s imperative to ensure a good 5-10 minutes of continuous stirring with a wide-bladed stick – not the screwdriver you used to prise the lid off!

Solid performer, but needs regular stirring

The vapour given off made us glad we were outside in the fresh air but the coating itself goes on in a thick and consistent way. In keeping with the other biocide brands on test, close inspection showed a solid performance with no signs of shell or weed growth – just the usual slime, especially around the waterline.

The comparatively high cost of the Seajet primer added a bit to the initial cost of application but in subsequent years the price comes down considerably.

Before a thorough wipe-down (left) and after (right)

18-month update

Sold as a premium self-polishing annual treatment for boats capable of up to 40 knots in areas of high fouling growth, this antifouling treatment still seemed to be performing well after 18 months on our static panel.

There was minimal surface growth and only a light smattering of slime. As expected, a certain amount of blue coating did release onto the sponge when the panel was wiped, suggesting it will eventually wear through and reminding us not to skimp when applying this type of erodible coating.

BEFORE (left): Shiny silicone- based foul-release system is available in several colours. AFTER (right): Almost no fouling bar some migration of growth from the dividing strip

Seajet Bioclean Eco

Type: Non-biocide, silicone based foul-release coating

Preparation: Three coats Seajet 117 Multipurpose Epoxy Primer; two coats Seajet Bioclean Tie-Coat; two coats Bioclean Eco

Initial cost: £1,012 inc primers

Lifespan: 3 years

Annualised cost over six years: £269

MBY rating: 4/5

Like Hempel’s Silic One, Seajet Bioclean Eco has a rubbery finish that fouling finds difficult to stick to. It is also a seven-coat system best used on bare gelcoat but can be applied on top of existing antifouling.

On bare gelcoat the process involves three coats of epoxy primer to provide a sound base, two coats of tie-coat, during which the colour element is introduced (black, white, navy-blue or red), then two coats of Bioclean-Eco – a transparent, paste-like substance.

When Raymariner was lifted, the majority of the test strip was admirably clean and shiny but there were some patches of fouling that appeared to have migrated across from the untreated dividing line separating this test patch from the neighbouring one rather than starting life on the black surface of Bioclean Eco itself.

3 year lifespan, but some fouling migration

Most of these dividing strips were painted with white International Trilux to avoid this happening but due to the longer application process of the silicone products we ran out of time on this one.

There was less slime than on the biocide products, and the wet microfibre towel test showed that it was easier to remove as well. Seajet expects this treatment to last for at least three years after which another tie coat and top coats should refresh it, although as this is a new product the recommended routine isn’t yet fully established.

Before a thorough wipe-down (left) and after (right)

18-month update

As with our other foul-release coating, this performed far better than expected on our static panel, suggesting it would still provide good protection on a less frequently used boat.

Fouling clearly finds it hard to adhere to its slippery, rubber-like coating even in a static situation like this and the swipe test suggests it would perform even better on a regularly used boat.

There were signs of isolated growth at the top and bottom but this could have been caused by migration of fouling from the untreated section between the two silicone-based coatings.

BEFORE (left): Ceramic Pro looks great above the waterline. AFTER (right): But it didn’t seem to deter fouling below the waterline

Ceramic Pro

Type: Biocide-free ceramic based nano-coating

Preparation: Smooth bare gelcoat

Initial cost: POA

Lifespan: N/A

Annualised cost over six years: N/A

MBY rating: 1/5 – for above-water use only

In fairness to Ceramic Pro, they were keen to be included as much for their own research as for ours to see if their protective coating, designed for use above the waterline, would also prevent fouling below it.

We know for a fact that it does a fine job protecting the topsides as Editor, Hugo, has used it to good effect on his own boat.

The super-smooth hydrophobic surface makes GRP easier to clean and it has become a popular treatment amongst professional boat valet companies, who find it provides a tough, permanent barrier against salt deposits, exhaust fumes, surface oxidation, staining, bird-droppings, and that ugly line of filth commonly seen around the boot-top, just above the waterline.

Great for topsides, not so good underwater

It was hoped that this would also prevent fouling from attaching below the waterline, however, the micro-organisms that lurk in the Solent’s tidal waters proved too persistent. Even though the fouling was not too difficult to remove, plant life had clearly taken hold and would have become worse over an even longer period of time.

Ceramic Pro told us pricing for boats is on a case-by-case basis and as a result, a price formula for our results table was therefore not deemed relevant.

18-month update: N/A

Buy it now from ceramicpro.co.uk

Note: We may earn a commission when you buy through links on our site, at no extra cost to you. This doesn’t affect our editorial independence.

The big antifoul test: Conclusions

Almost all of the coatings did an effective job of keeping fouling at bay but there were some notable differences between them, not just in terms of performance but also cost, application time and environmental credentials.

We have based our star ratings on all four factors over a nominal six-year period, albeit with a bias towards how well they fulfil their primary role of keeping your boat fouling-free. However strong the eco-credentials, if it fails to do its job you will end up burning more fuel and releasing more pollutants into the atmosphere.

In the event, the silicone-based biocide-free foul-release coatings performed remarkably well, especially Hempel’s Silic One. If you can put up with the higher initial cost and time taken to apply these products for the first time, they really do deliver on their promise and over six years the annual price is broadly comparable.

They won’t suit every boat, though, as silicone can dry out if left unsubmerged for long periods and may start to wear through if kept on a trailer, dry-stack or drying-mooring, but for most craft they appear to be a very effective alternative to conventional biocides.

Coppercoat’s tough finish is fine to use in any of these situations and has the next best eco-credentials of our group. It performed almost as well as the traditional annual antifouls over a short period but should carry on delivering strong results for ten years or more.

It does have to be applied to bare gelcoat, though, which can push up the initial cost. On our fictional 36ft boat we calculated the break-even point at about six years but this would come down substantially if you included the annual labour cost or were applying it to a brand new boat that didn’t need stripping first.

There was little to choose between the traditional biocide antifouls, which supports the view that if you prepare the surface well and apply it properly, most antifouls will do a decent job of protecting your boat, at least over the course of a single season in UK waters.

Hempel’s budget offering, Tiger Xtra, delivered decent protection at a great value price, while Seajet Shogun, International Ultra 300 and Jotun Non-Stop all gave a solid, reliable performance and were impossible to split during the course of our initial test period.

The panel-back after 18 months without antifoul

18-month update conclusions

While the results of the long-term panel test have helped to back up the findings from our original boat-based test, there was not a big enough difference between the performance of the various different coatings to justify changing any of our original boat-based star ratings.

All seven products provided a good degree of antifoul protection when compared with the growth on even the smallest untreated sections of the panel. The extra fuel cost in dragging a carpet of unsightly fouling like this on the underside of your hull does not bear thinking about.

Our tests prove that even a moderately priced traditional copper biocide can provide all the short-term protection you need. But be prepared to keep an eye on soft, self-polishing and erodible coatings such as Seajet Shogun, Hempel Tiger Xtra or Jotun NonStop 2, because they will need topping up each year or re-applying in full every two seasons.

The fact that our test panel wasn’t moving may have helped extend the life of these products. Hard coatings such as Coppercoat or International Ultra 300 lend themselves to the extra friction from faster hulls but may need occasional scrubbing to maintain their performance when the surface layer starts to lose its potency.

The sponges used for the wipe test

They are designed to withstand being scrubbed and should not get damaged if you keep your boat on a trailer or in a dry-stack. However, on the basis of this long-term panel test, they seemed to maintain their performance for the full 18 months without any intervention and in the case of Coppercoat should carry on doing so for years to come.

If you’re willing to invest the extra time and cost of applying a silicone-based foul release coating, either of the two that we tested will, on the evidence of this test, do a very good job for you, even if your boat isn’t used that regularly.

The fact that they do this without the use of biocides can only be a good thing for the long-term health of our rivers and seas. You do need to follow the instructions carefully, because each of the three stages of primer, tie-coat and top-coat need correct application for the coating to perform well as a whole.

However, once applied, they should last for several years but tread cautiously with your annual maintenance routines, because a powerful pressure-washer can dislodge the layers if held too close.

First published in the April 2022 and May 2023 issues of MBY.

If you enjoyed this…

Be first to all the latest boats, gadgets, cruising ideas, buying advice and readers’ adventures with a subscription to Motor Boat & Yachting. Available in both print and digital formats, our monthly magazine will be sent directly to your home or device at a substantial discount to the usual cover price. See our latest offers and save at least 30% off the cover price.