MBY editor Hugo Andreae explains why antifouling your boat is so important and how to do it right

What are the current options?

The three main choices for leisure boaters are to paint it with some form of eroding antifouling, to coat it with a semi-permanent copper treatment, and to prevent build up of growth by keeping it clear of the water or regular scrubbing of the hull.

Which is best?

Theoretically, the last. A polished gel-coat will slice through the water with less drag than a hull painted with a soft, copper oxide-based antifouling.

This means it will be faster and more fuel efficient (a 34-knot boat can lose up to two knots from paint alone). It is also the most environmentally sound option.

But unless you own a boat you can keep out of the water on a lift or dry-stacking system, it is also a pain in the butt. Even a new polished hull will need scrubbing down every few weeks, while a scratched or pitted one will attract growth in a matter of days.

How do the other systems work?

Antifouling paints and semi-permanent treatments rely on a variety of biocides to deter and if necessary kill organic matter.

The main biocide in paints is usually a compound of copper, such as copper oxide or copper thiocyanate, which is boosted by co-biocides targeting specific types of algae and slime.

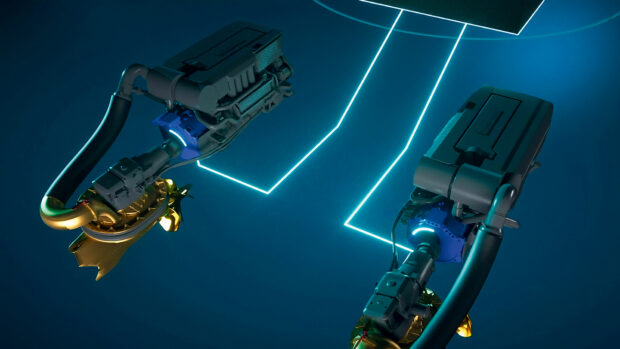

Longer-term treatments, such as those offered by Cuprotect (pictured below) and Coppercoat, rely on copper alone, usually in the form of tiny copper granules sprayed onto or suspended in a non-eroding resin coating.

Which system works best?

There is no definitive answer to this but as a very broad generalisation, a conventional eroding antifouling paint tends to be very effective initially but then becomes gradually less so over time, while semi-permanent coatings should maintain a similar, but arguably slightly less effective level of performance year after year.

Why does antifouling paint become less effective over time?

Because nearly all ablative paints work in a similar way. The active biocides, such as cuprous oxide, and the other algaecides are held in an inert resin paint matrix (usually made up of binders, solvents, pigments and small amounts of other additives).

Once submerged in water the active biocides gradually leach out of the paint matrix to deter any growth, leaving behind a honeycomb of ‘dead’ paint.

Most of this will be worn away by the action of the boat moving through the water (or in tidal berths, the water moving past the boat) to reveal a fresh layer of biocide-laden paint.

The problems tend to occur when boats are left unused for extended periods of time in non-tidal berths. This allows a thicker layer of dead paint to form, which slime and barnacles can settle on.

Do some antifouling paints last longer than others?

Yes. By fine-tuning the leach rate of the biocides and the eroding properties of the paint matrix, manufacturers can extend the life of paint to two or more seasons. However, this doesn’t get around the problem of boats being left unused for long periods of time.

Are there any exceptions to this rule?

Yes. True self-polishing copolymers, such as the tributyl tin (TBT) paints of the 1980s, maintain the same high level of performance regardless of whether the boat is static or moving.

This is because they don’t rely on the physical action of water passing the hull to erode away the paint and leach out the biocides, but on a chemical reaction with the water itself.

The active biocide, tributyl tin oxide, is a colourless soluble product that is chemically part of the paint matrix itself. As the TBT is exposed to water it reacts to form a soluble compound that dissolves into the water.

This exposes a brand-new layer of fresh biocide-laden paint and means that performance is consistent even when the boat is lying in the marina.

It also prevents the annual build-up of paint, can be brightly coloured or left clear, and may even make older boats faster by smoothing out imperfections in the hull surface. It was the Holy Grail of antifouling paints!