Recently launched on the Isle of Wight, Arksen’s new British-built explorer yacht is designed to survive everything from ice floes to a 360° roll with eco credentials to match...

The first Arksen 85 has been launched on the Isle of Wight and will now undergo sea trials before handover to her private owner, the British yard has announced.

Currently known as Project Pelagos, Hull no1 will primarily be used for Mediterranean family cruising, but the owner was keen to have the ability to cruise further afield when the opportunity arose.

The owners choice of manufacturer was in part because of the company’s mission to reduce its impact and give back to the ocean.

“Buying into Arksen’s unique concept is giving the new generation of these explorer enthusiasts the possibility, not just to visit the last great wilderness of our planet, but also to contribute to its protection and regeneration actively,” said the owner of Project Pelagos.

“I believe this pioneering and refreshing path that Arksen is taking will make them a driving force in the future of the explorer yacht industry.”

Hull no2, Project Ocean, is due for completion before the end of the year and will be available for public viewing.

Article continues below…

Arksen Yachts reveals plans for first three British-built explorers

Antarctic adventure: Cruising through the Lemaire Channel on FPB 78 Iron Lady

Read on to find out what Dave Marsh learned about the project when he went behind the scenes at the yard’s HQ last summer…

What makes a motor boat an explorer yacht? Well, for most boat builders, it’s no more than a stylistic exercise, a gentle reimagining of their otherwise conventional powerboats, courtesy of upright pilothouse windows, a plumb bow, and maybe a few overly sturdy cleats that look like they’ve been appropriated from a posh workboat.

Nothing wrong with that of course; who amongst us hasn’t narrowed down our choice of car or boat or house based on looks alone, long before we properly delve into its functionality?

There is a different breed of explorer, though, the type of vessel engineered in such a way that nudging through ice floes would not give you sleepless nights, and designed so that heading off across the Atlantic will not have you suffering from the electric car driver’s ever-present paranoia – range anxiety.

A boat where function is the underlying driving force behind the design, albeit that its looks may be alluring anyway. This type of explorer is a rare beast indeed. Arksen’s new 85 fits resolutely into this category. So why didn’t it turn out like a burly Nordhavn? Or an elegant Fleming?

For those of you who believe that its closest philosophical companions are the FPBs (Functional Power Boats) that Steve Dashew designed and immortalised, you would be right.

But you would be wrong to also assume that these two serious explorer yachts are like peas in a pod – under their alloy skins they are quite different, most notably in the technical department. So exactly how did the Arksen 85 develop in the way it did?

The Arksen philosophy

Mountaineer and adventurer Yvon Chouinard is the founder of Patagonia, a clothing company that committed itself to environmental activism long before most of the planet’s inhabitants were even aware of the notion.

In 1985 Chouinard co-founded ‘1% for the Planet’ by pledging to voluntarily donate 1% of Patagonia’s sales to “the preservation and restoration of the natural environment”. Patagonia began manufacturing clothing made from polyester recycled from plastic soda bottles ten years before Greta Thunberg was born.

Fast forward to the present and the world’s PR departments are busy bombarding us with unsubstantiated environmental claims to boost their eco credentials. So it might sound trite to suggest that the Arksen 85’s development was driven by similar philosophical ideas to Chouinard’s – we all need clothing, none of us ‘needs’ an 85ft explorer yacht.

However, conversations with Arksen’s founder, Jasper Smith, and his colleagues, along with Arksen’s documented commitment to all manner of philanthropy and environmental research, suggest that Jasper (who is also a mountaineer) is genuinely inspired by Chouinard’s values, and is clearly striving to mitigate the impact of his creations as much as is humanly and technically possible.

So how has Arksen gone about achieving this goal? There are two key strands; recycling and operational efficiency. At its simplest, the former is fairly straightforward, basically use as high a percentage of recycled and/or recyclable material as possible.

For example, the team responsible for the interior, Design Unlimited, has utilised recycled cotton yarns, cork walls, reclaimed wooden panels, and materials made from recycled plastic bottles on the first Arksen 85.

Scale model highlights the vessel’s mighty framing system

The recycling biggie though is unquestionably the 85’s construction material – aluminium – which comprises a huge part of the Arksen 85’s 66 tonne un-loaded mass. Easier to process than steel, aluminium can be recycled in perpetuity.

Currently, Arksen’s aluminium alloy contains up to 40% recycled material, but the company may switch to a supplier whose alloy has up to 70% recycled content.

Supreme fuel efficiency

The naval architects tasked with making the Arksen 85 as fuel efficient as possible were HYD (Humphries Yacht Design) with father-and-son principals Rob and Tom famous for their elegant, slippery sailing boats. HYD’s brief was for a boat capable of travelling faster than the maximum 11 knots or so that a heavy full displacement hull form would have been limited to.

The Arksen range is entirely British-designed and built

This is the main reason why the Arksen 85, and its smaller Arksen 75 and Arksen 65 siblings, bear little relation to the heavyweight craft from Nordhavn. A quick comparison with the Nordhavn 76 explains a lot. At 9 knots, the Nordhavn 76’s fuel consumption is 48lph.

That’s not at all bad for a colossus weighing in at around 100 tonnes. Nevertheless it is around twice the (albeit estimated) fuel burn of the 66 tonne Arksen 85 at the same speed.

Speed up just two knots, to the Nordhavn 76’s top speed of around 11 knots, and the Arksen 85’s slippery semi-displacement hull form is still only consuming an estimated 50lph, whereas the Nordhavn 76’s fuel burn has climbed to 159lph.

Turning the sturdily built aluminium hull

Testing, testing

To ensure the Arksen 85 was as efficient as possible, HYD ran various ‘What if?’ hull forms through their CFD (Computational Fluid Dynamics) programmes before settling on an optimum design.

The designers then conducted extensive tank test programmes, run at two separate sites. This involved towing a large-scale model in waves to assess its behaviour, and in flat water to confirm the drag and fuel consumption data from the CFD programmes.

There is another significant facet of the 85’s potential fuel efficiency. Films of Steve Dashew’s FPB hulls have shown that in the right conditions they are capable of surfing downwind and in quartering seas at 20 knots or more, massively cutting per-mile fuel consumption.

Rob and Tom’s semi-displacement hull form has far broader and flatter stern sections than the FPB’s, which should further boost the 85’s potential surfing speeds.

The first boat is also equipped with Swedish company Humphree’s excellent interceptor trim system, running right across the transom, which will allow the skipper to fine tune the trim of the boat to suit the conditions, and not just in surfing mode.

The Incredible Hulk

One of Rob and Tom’s main developmental challenges was satisfying Arksen’s aim to make its intrepid explorers to all intents indestructible, the marine equivalent of The Incredible Hulk. However, add too much structural weight and Arksen’s target of a 14-knot top speed, a 7,000 mile range (at 9 knots) and the ability to surf becomes unattainable.

Arksen’s regulatory starting point was not exactly undemanding; to build the boat to commercial (not leisure boat) regulations, specifically the UK MCA Workboat Code Category 0 for unrestricted ocean voyaging.

However, despite also designing the structure to comply with Lloyds Register SSC (Special Service Craft) the team decided to selectively exceed the required scantlings in places.

So, the welders working for the builders chosen to fabricate the aluminium structure, Wight Shipyard on the Isle of Wight (who have a history of building large commercial aluminium vessels) found themselves welding 8mm topsides instead of 6mm; 12mm bottom plates where 9mm would have kept Lloyds happy, and most significantly, a monumental 20mm-thick full-length keel plate.

Along with the ability to take to the ground, the main driver for this robust construction was to allow the boat into high latitudes where she might encounter fragmented ice floes. Arksen also wanted the 85 to be able to cope with the unlikely event of a freak wave rolling the boat. Fitting the superstructure with toughened glass that varies in thickness from 19mm to 25.5mm will doubtless keep the water out.

The main helm is in the pilothouse, but the Arksen 85 can also be piloted from below

Keeping the water at bay has also allowed HYD to design the Arksen 85 with “180° positive stability in all expected operation load conditions”. I wouldn’t expect the Arksen 85 to pop upright in seconds like a self-righting lifeboat, rather I’d anticipate a more composed recovery.

Having scrutinised first hand the Hulk-like build and the progress of its construction at Wight Shipyard, I can vouch that no boat I have been onboard would give me more reassurance in survival conditions.

Steady as she goes

Arksen’s development teams also spent considerable time investigating the pros and cons of different stabilising systems. For an intrepid explorer yacht in particular, conceivably voyaging offshore in big seas and stormy conditions, the issue of stability extends far beyond the idea of not spilling the guests’ G&T.

With potentially no convenient safe haven to run for, onboard safety is paramount – crew cannot afford to fall and break bones, and minimising seasickness becomes more imperative. There’s an important efficiency angle too that accords with Arksen’s aim of reducing its boats’ environmental impact by minimising fuel consumption.

Boats that roll around from side to side waste energy and experience higher drag than boats which remain largely upright, and there’s no point spending a fortune testing and developing the optimally fuel-efficient hull form if the underwater shape actually ploughing through the water is all to cock.

But what to fit; gyros or fins? Both have distinct strengths and weaknesses. Fortunately for Arksen, the first 85 owner has gone for broke and specified both systems, plus those aforementioned Humphree interceptors too.

The first Arksen 85 sports three symbiotic stabilising and trim systems

Better still, the three systems have not been scaled down to compensate for each other. For example, the 1.3m² zero-speed fins are exactly what Humphree recommended for the Arksen 85 on the assumption of no gyro.

In fact, the first 85 has two Seakeeper gyros, a versatile arrangement comprising a 9 and an 18 model in place of a single 26. Along with the Humphree interceptors, this will give Arksen an unprecedented opportunity to weigh the myriad pros and cons and to guide future owners depending on their operational needs.

Personally, I reckon that the hybrid system will conjure stability nirvana for Arksen 85 owners, with the gyros providing unmatched stability at rest, and the fins largely handling things on the move thanks to their ability to correct for wind-induced heel and to provide an uninterrupted correcting stabilising force underway.

The owner of hull no2 commissioned a tranquil look from Design Unlimited

Power to the people

With the worldwide rush to electrify everything in sight, in the pursuit of zero-carbon, it’s no surprise that the development of the Arksen 85 included a hybrid propulsion option alongside more conventional diesel engines, which in the 85’s case comprise a pair of 8.9 litre heavy duty 330hp (246kW) Cummins QSL9.

The price premium for the Arksen 85 hybrid sounds eye-watering, but only because half a million pounds is a lot of money. If you compare the cost of hybrid and non-hybrid versions of otherwise identical cars, the £6.5 million Arksen 85’s hybrid premium of 8% is actually very reasonable, especially when you consider that it’s not a mass market automotive product but a custom boat.

Arksen was keen to have a single supplier for the entire hybrid system, so it went to long-established (1965) commercial technology developers and manufacturers Praxis.

At its heart, the serial hybrid system supplied by Praxis comprises three 268hp (200kW) 3-litre diesel generator engines, two 80kWh lithium ion battery banks, a pair of 250kW electric motors, plus the entire gamut of control and monitoring and power management systems.

Arksen claims that its “hybrid propulsion option provides increased efficiency, lower emissions and allows silent running”. To that statement I would add, “that depends…”

The hybrid system has to pass power from the 200kW generators (which are basically diesel engines bolted to an electric generator/alternator) through complex power conversion electronics and chunky cabling and inverters and conceivably additional cooling circuits, too, before finally passing into the electric motors – and all these processes incur losses.

If the power first goes into the batteries and then out again for silent electric-only running, those losses are higher still. That said, as a boat’s speed drops, the typical diesel engine and propeller setup can become very inefficient, whereas serial hybrid losses remain more constant.

All told, I suspect that the Praxis-propelled Arksen 85 will prove more fuel-efficient at low speeds, but that there will be a crossover point where the old-fashioned diesels pull ahead, in the vicinity of typical cruising speed/revs, increasingly the zone which modern marine diesels’ fuel efficiency and torque is optimised for.

Whatever propulsion system the owners chose, there’s the possibility of free fuel, courtesy of the optional PVC (photovoltaic cells) that cover much of the roofs of the upper and lower deck.

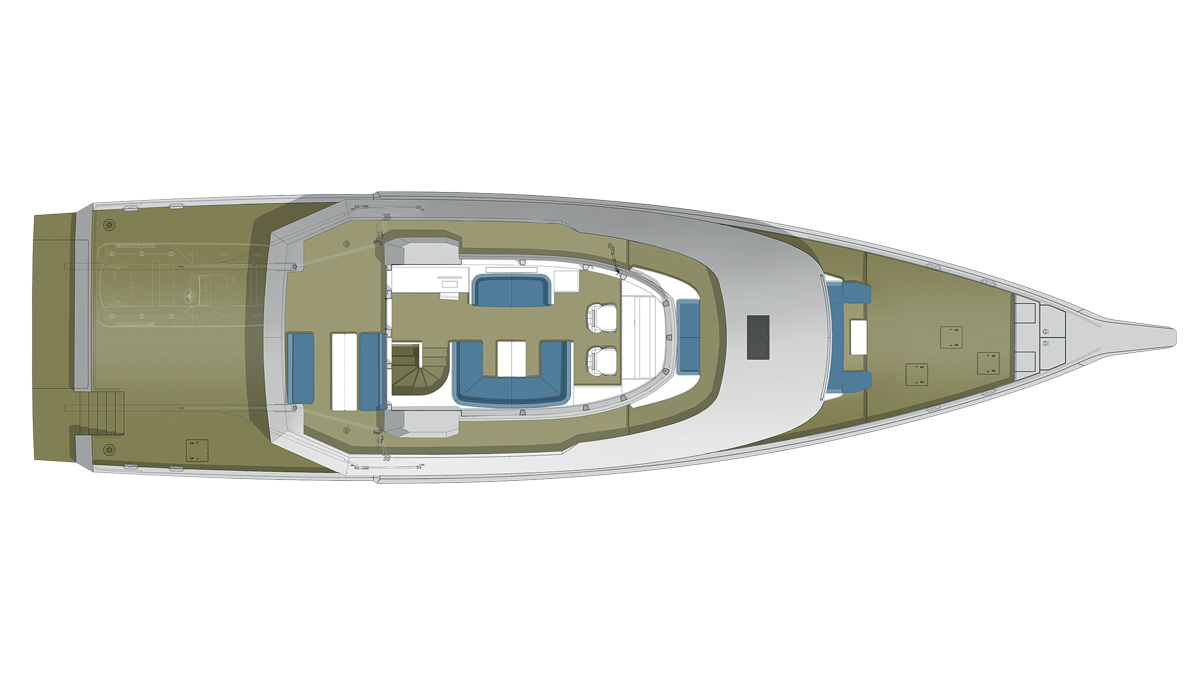

These are the standard layouts, but multiple mix and match options are available

These provide a theoretical maximum 7kW of electrical energy, although technical director Jim Mair is estimating a typical real-world 5kW in bright sunny conditions. Although this is not yet enough to cover the 85’s regular hotel loads, the onward march of technology never ceases, and this particular field is ripe for a paradigm change.

Invincible?

Putting aside Arksen’s wider philanthropic and environmental ambitions, at the heart of the Arksen project is a desire to produce an invincible boat, a vessel that will safely carry its passengers anywhere in the world, in any conditions.

We’ve only been able to cover the major developmental issues, but delving into its meticulous 74-page build specification I discovered all manner of things which help explain the Arksen 85’s £6.5 million price. To reduce noise to a minimum, the hull is lined with sound-deadening and heat-insulating material.

Even the deep aluminium frames that remain exposed are all sprayed with a remarkable insulation that dampens sound and made them feel lukewarm to the touch, even in winter in a boatyard.

“At the heart of the Arksen project is a desire to produce an invincible boat”

Assembling more than 20 tonnes of raw aluminium into a highly complex organism does not come cheap, and nor does building to Class. That Classification demands far more than compliance with stringent regulations. For example, every single hull weld will be subject to a non-destructive dye test to check its integrity.

Despite their very different characters and construction, it is inevitable that explorer aficionados will weigh the accommodation on the Arksen 85 with similarly indestructible explorers, in particular the vessels from Nordhavn.

When I visited Wight shipyard in February, there was no furniture in place, so it’s not yet possible to compare fit and finish. Although it is a towering colossus, the Nordhavn 86 does seem like the fairest comparison; it’s a smidgen shorter but a little wider, it has a genuine tri-deck layout, and it is far closer in price to the Arksen 85 than the Nordhavn 76.

Arksen’s 85 fares extremely well in the cabin stakes; both boats have four double cabins as standard, but the British-built boat sports an even more palatial owner’s en-suite stateroom.

But then the Arksen 85 allocates about 26% of its lower deck length to the engineroom and lazarette, whereas the Nordhavn 86 devotes 38% of its length to the same two spaces, even excluding its lengthy pump and tank room forward.

On the main deck, tenders and toys are stored on the Arksen 85’s aft deck, but on the Nordhavn 86’s they’re stored on the foredeck, and let’s not forget that the Nordhavn 86 has an ‘extra’ flybridge atop its three decks. The US boat wins a convincing top trumps in saloon real estate, not least because its enormous galley utilises the boat’s entire beam.

“No boat I have been onboard would give me more reassurance in survival conditions”

Mind you, on the first boat, Arksen’s designers have deliberately sacrificed the back end of the saloon to create a sort of air lock, a separate area that can be closed off from the saloon and the aft deck creating the perfect space to change in and out of wet oilskins, and to prevent cold air, grime and water being dragged into the saloon. It’s a brilliant idea.

Another lovely design touch is Arksen’s decision to utilise curved windows for the front screens. It’s an expensive direction to take, but it looks terrific and hugely increases the windows’ impact strength in the event of a giant wave roaring down the foredeck and crashing onto the lower deck screens.

The more I think about this remarkable boat, the more I’d like to be there when that happens.

First published in the July 2022 issue of MBY.

If you enjoyed this…

Be first to all the latest boats, gadgets, cruising ideas, buying advice and readers’ adventures with a subscription to Motor Boat & Yachting. Available in both print and digital formats, our monthly magazine will be sent directly to your home or device at a substantial discount to the usual cover price. See our latest offers and save at least 30% off the cover price.

Photovoltaic panels should generate circa 5kW in sunny conditions